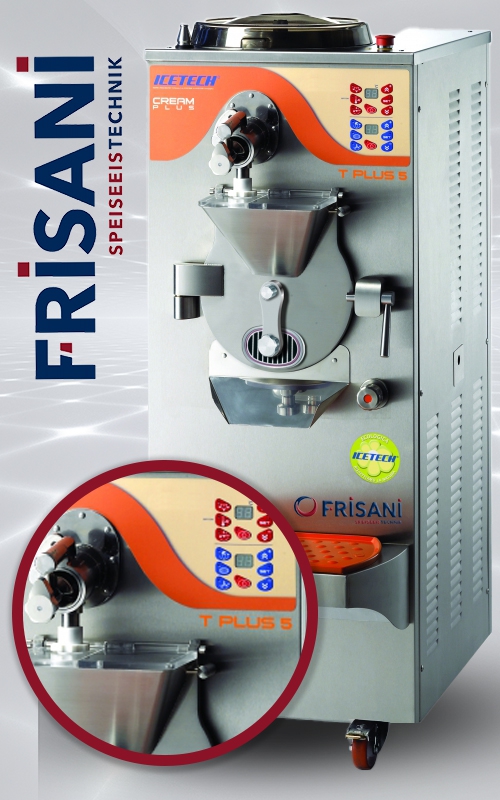

Icetech Ice Cream Machine TP 5 Cream Plus Made in Italy

Icetech Ice Cream Machine TP 5 Cream Plus Made in Italy

€35,800.00

Net plus VAT – Export Tax Free

Description

The CREAM PLUS machine is produced in four versions 3-4-5-7 and is a real jewel for ice cream parlors and confectioneries because it is made with the most modern mechanical, electrical and cooling components.

In the upper tray, the unit heats and cools with the “water bath” system with glycol, which prevents the formation of deposits and allows to prepare ice cream mixes, delicious pastry creams (by pulse mixing), tasty jams and inverted sugar, as well as soften chocolate.

In the stirring chamber, the device works like a normal ICETECH series stirrer with the latest technology to produce amazingly dry and high quality ice with appropriate consistency in optimal yield and quality.

COOLING / HEATING TRAY:

The upper tank operates absolutely independently of the stirring chamber in the lower section; the product can not only be heated, but also cooled and kept at a temperature above zero degrees set by the user. Through the practical withdrawal tap can:

- The ice cream mixture can be quickly and easily put directly into the mixer.

- Confectionery cream (and other recipes) can be conveniently placed in a tub without going through the mixing chamber.

- Cleaning and sterilization of the device can be performed quickly and perfectly in accordance with the strictest hygiene regulations.

PIPE CHAMBER

After the user has added the mixture to the mixing chamber via the stove tap, the mixing, which is automatically controlled by a microprocessor, is initiated. As with our new MT 3/4/5/7 mixers, the electronic control also has a “WATER ICE” function.

| Hourly production | 20/65 kg |

| Capacity upper tray | min. 2 l max. 14 l |

| Capacity lower tray | min. 4 l max. 8 l |

| Current consumption | 10 kW |

| Electrical properties | 400 V / 50 Hz / 3 Ph |

| Compaction | Water |

| Cooling gas | R 404 A |

| Size | 535 x 715 x 1400 mm |

| Weight | 290 kg |

The following applies to all used machines offered by us:

- Overhauled with replacement of defective components with original spare parts

- Technical parts dismantled, cleaned inside and out

- Replacement of defective wearing parts and installation of original spare parts in our workshop area

- Updating the refrigeration system in accordance with EC Regulation 1005/2009 for banned refrigerants such as R-502 and R22

- Satin finishing and reconditioning of stainless steel surfaces with CNC ceramic grinding technology

- Multiple test runs with workshop logging by the respective skilled worker

- Supplied with cooking magnifier and operating instructions from the respective manufacturer

Assembly and installation possible on request.

Warranty

1 year warranty from the date of delivery

Right of exchange

14 days exchange right from delivery date

Delivery included

Free delivery within Germany