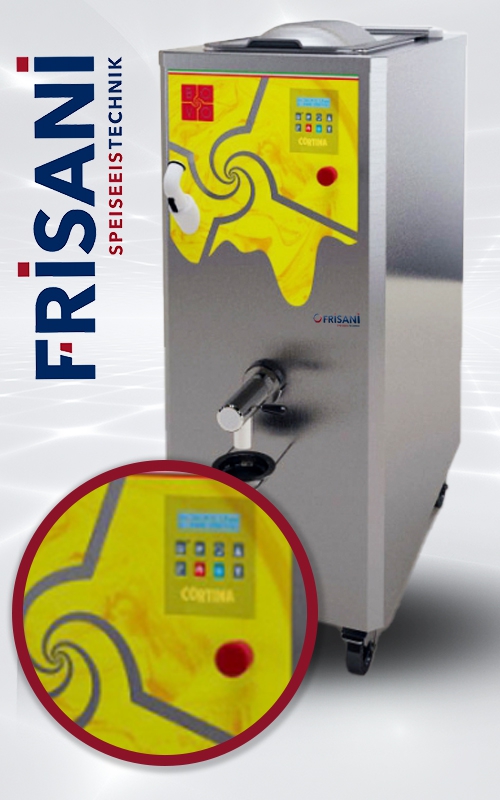

BOVO Cortina 180 pasteurizer

Description

The Cortina pasteurizer series is able to satisfy the professional requirements of the treatment of the mixtures: Preparation, pasteurization, emulsification, preservation and maturing, with high quality standards, functionality and reliability.The Cortina pasteurizer series offers two lines: The Cortina Basic and Plus pasteurizers are equipped with seven programs that guarantee perfect control of the pasteurization temperature, high pasteurization, low pasteurization, pasteurization of mixtures for chocolate, custom pasteurization and canning; they also guarantee maximum control and constant temperature during the maturing of the mixture. Two cleaning systems are available: Cold rinse or hot cleaning.

- The Cortina pasteurizer tank is made of a steel monoblock with rounded corners. The bottom is beveled to facilitate the outflow of the mixture. The inside of the tank is graduated so that the quantity inside can always be checked.

- The outlet tap is completely realized in stainless steel and can be disassembled. It is equipped with a cleaning device that can be applied after each outlet; it is also equipped with a return piston that pushes the mixture back after each extraction.

- The agitator reaches a speed of up to 2500 rpm thanks to the inverter. The speed varies according to the pasteurization process and guarantees a better distribution of the ingredients during the filling phase.

- The heating system is carried out by means of a water bath; the mixture is continuously stirred, thus improving heat transfer and preventing it from burning due to sticking.

- Cooling is carried out in such a way as to ensure even distribution of cold, thus preventing freezing on the side walls. The outlet tap is also cooled.

- The support bracket with drip catcher is made of stainless steel, can be disassembled and also cleaned in the dishwasher. The container for mixture removal can be placed on it to avoid contact with the floor.

The technological solutions applied by Bovo to the Cortina Basic and Plus pasteurizers allow to improve the quality of the ice cream structure. Some particular processing phases are accelerated and simplified, as well as the cleaning and control of the machine:

- Due to the speed and regulation of the flow of the mixture in the tank, enabled by the inverter, the agitator can reach up to 2500 rpm. reach In this way, a mixture is obtained in which the ingredients are better distributed, uniform and coherent: this subsequently allows the production of an ice cream characterized by a finer texture and greater stability;

- For those who use milk and cream partially or completely in powder form, the speed control by the inverter allows better dissolving and hydrating of the powder;

- For the disinfection of the machine, a specific program of automatic cleaning is applied: after the inlet of water into the tub in the necessary quantity, it is heated and automatically distributed by stirring.The user only has to add a specific detergent and mechanically remove any residues, if necessary, after switching off the machine (this may prove necessary if the machine is not cleaned after each pasteurization cycle). It is recommended to use a special detergent, such as Bovo Clean Forte, which perfectly cleans and disinfects the machine.

| Hourly production | 180 l |

| Time per cycle | 2 h |

| Cooling | Water |

| Cooling gas | R 452A |

| Electrical connection | 400 V/50 Hz/3 |

| Nominal power | 18 kW |

| Dimensions LxWxH | 700x1050x1160 mm |

| Net weight | 322 kg |

Warranty

3 years warranty from the date of delivery

Funding

0% financing on all Telme models

Delivery included

Free delivery within Germany